Epoxy Flooring Myths, Eco-Friendly Options & Safety

Confusion surrounds epoxy flooring like fog on a winter morning. Homeowners and business owners in Rock Hill, SC often make costly decisions based on outdated information and persistent myths about epoxy floors. These misconceptions spread faster than spilled paint, affecting how people think about this flooring option.

The truth is that modern epoxy technology has advanced far beyond what many people understand. New eco-friendly formulations and safety improvements have changed the game completely. Yet old myths continue to influence choices, sometimes preventing people from selecting the perfect flooring solution for their needs.

This guide will separate fact from fiction about epoxy flooring. You’ll discover the real truth about safety, environmental impact, and performance. More importantly, you’ll learn about sustainable epoxy options that protect both your family and the planet.

Table of Contents

Common Epoxy Flooring Myths Debunked

Myth #1: Epoxy Floors Are Always Slippery

Fiction: All epoxy surfaces create dangerously slippery conditions that lead to falls and accidents.

Fact: Modern epoxy systems include many slip-resistant options that actually improve traction over bare concrete.

Top Flight Garage Floor and other professional installers regularly add slip-resistant additives to epoxy coatings. These include:

- Textured finishes – Create subtle surface patterns that improve grip

- Decorative flakes – Add both beauty and traction to the floor

- Aluminum oxide additives – Provide excellent slip resistance without compromising appearance

- Shark-grip additives – Create aggressive non-slip surfaces for wet areas

Professional epoxy floors can achieve coefficient of friction ratings that exceed safety standards for commercial buildings. Many hospitals, schools, and restaurants choose epoxy specifically because it can be formulated for superior slip resistance.

The key lies in proper product selection and professional installation. Different environments require different slip-resistance levels, and experienced contractors know how to match the right system to each application.

Myth #2: Epoxy Coatings Don’t Last Long

Fiction: Epoxy floors need replacement every few years, making them a poor long-term investment.

Fact: Quality epoxy installations regularly last 15-20+ years with proper maintenance and professional application.

The lifespan of epoxy floors depends on several critical factors:

Surface Preparation Quality – Proper concrete preparation accounts for 80% of epoxy success. Professional contractors use diamond grinding, shot blasting, or acid etching to create the right surface profile.

Material Quality – 100% solid epoxy systems significantly outlast water-based products. Premium materials cost more upfront but provide superior longevity.

Application Technique – Professional installers understand proper mixing ratios, temperature control, and application methods that DIY approaches often miss.

Maintenance Requirements – Regular cleaning and occasional recoating can extend epoxy life well beyond two decades.

Compared to other flooring options, quality epoxy offers exceptional durability. While carpet might last 5-10 years and vinyl tile 10-15 years, professional epoxy installations commonly exceed 20 years of service life.

Myth #3: All Epoxy Products Are the Same

Fiction: Any epoxy coating will produce identical results regardless of brand or type.

Fact: Dramatic differences exist between product types, quality levels, and performance characteristics.

Understanding epoxy classifications helps explain these differences:

100% Solids Systems – Contain no solvents or water, providing maximum durability and chemical resistance. These professional-grade products offer the longest service life.

Water-Based Systems – Easier to apply but provide limited durability and chemical resistance. Better suited for light-duty residential applications.

Solvent-Based Systems – Offer good performance but include VOCs that affect indoor air quality. Less common due to environmental concerns.

Industrial Grade vs. DIY Products – Home improvement store epoxy typically contains 30-50% solids content, while professional systems often exceed 90% solids.

Manufacturer specifications reveal huge performance differences. Premium systems might withstand 200+ degrees Fahrenheit, while basic products fail at 140 degrees. Chemical resistance, abrasion resistance, and UV stability also vary dramatically between products.

Myth #4: Epoxy Installation Is Always a DIY Project

Fiction: Anyone can achieve professional-quality epoxy results with basic tools and weekend effort.

Fact: Surface preparation and application require specialized skills, equipment, and experience that most homeowners lack.

Common DIY failures include:

- Inadequate surface preparation – Results in poor adhesion and premature failure

- Incorrect mixing ratios – Leads to soft, tacky surfaces that never fully cure

- Temperature/humidity mistakes – Causes bubbling, poor flow, or adhesion problems

- Application errors – Creates uneven coatings with visible lap marks

Professional contractors use specialized equipment like walk-behind grinders, shot blasters, moisture meters, and commercial mixing systems. This equipment costs thousands of dollars and requires training to operate safely and effectively.

Simple garage floors with basic color requirements might work for DIY installation. Complex projects involving multiple colors, decorative elements, or demanding performance requirements benefit significantly from professional installation.

Top Flight Garage Floor has seen many DIY projects that required complete removal and reinstallation. The cost of fixing failed DIY epoxy often exceeds the original professional installation price.

Myth #5: Epoxy Floors Are Only for Garages

Fiction: Epoxy coatings are limited to automotive spaces and industrial applications.

Fact: Versatile epoxy systems work beautifully in residential, commercial, and industrial settings across many different environments.

Popular epoxy applications include:

Residential Spaces – Kitchen floors, basement finishing, laundry rooms, workshops, pool decks Commercial Buildings – Retail spaces, restaurants, offices, showrooms Institutional Facilities – Hospitals, schools, laboratories, government buildings Industrial Settings – Manufacturing plants, warehouses, food processing facilities

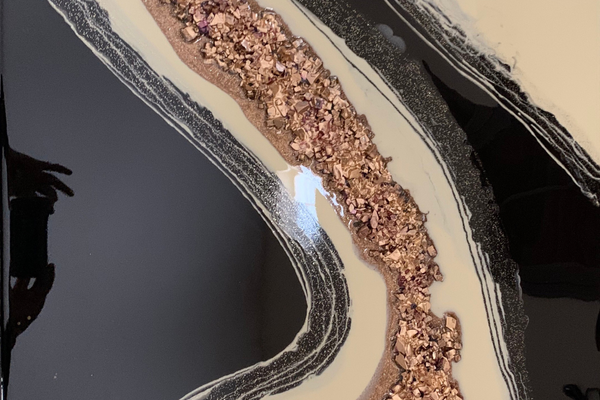

Decorative possibilities have expanded dramatically. Modern epoxy can mimic:

- Metallic finishes with swirling patterns

- Terrazzo appearances with decorative chips

- Natural stone textures and colors

- Custom logos and designs

Design flexibility allows epoxy to complement any architectural style. From rustic farmhouse kitchens to ultra-modern office buildings, epoxy adapts to match aesthetic requirements while providing superior performance.

Myth #6: Epoxy Emits Dangerous Fumes Forever

Fiction: Epoxy floors continuously release harmful chemicals into the air throughout their service life.

Fact: Properly cured epoxy becomes chemically inert and stops emitting VOCs after the curing process completes.

Understanding the difference between installation and long-term emissions is crucial:

During Installation – Fresh epoxy releases VOCs as solvents evaporate and chemical reactions occur. Proper ventilation during this period is important for occupant safety.

After Curing – Fully cured epoxy forms a stable polymer that doesn’t continue releasing chemicals. This process typically completes within 7-30 days depending on the system.

Long-Term Air Quality – Cured epoxy actually improves indoor air quality by sealing concrete and preventing dust generation. Many epoxy systems earn GREENGUARD certification for low emissions.

Professional installation includes proper ventilation protocols during application and curing. Quality contractors plan installation timing to minimize occupant exposure and provide clear guidelines for safe reoccupancy.

Understanding Eco-Friendly Epoxy Options

What Makes Epoxy Environmentally Friendly

Environmental considerations in epoxy selection go far beyond simple VOC content. Modern eco-friendly epoxy systems address multiple sustainability factors:

Low or Zero VOC Formulations – Advanced chemistry eliminates or minimizes volatile organic compounds without compromising performance. These systems improve indoor air quality while reducing environmental impact.

Solvent-Free Systems – Eliminate petroleum-based solvents entirely, reducing air pollution and disposal concerns. 100% solids formulations provide this benefit while offering superior durability.

Recycled Content – Some manufacturers incorporate post-consumer recycled materials into epoxy formulations. Glass content and recycled aggregates reduce virgin material consumption.

Energy Efficiency Benefits – Epoxy’s reflective properties reduce lighting requirements, lowering energy consumption. Light-colored epoxy can reflect up to 90% of available light, significantly brightening spaces.

Lifecycle Advantages – Long service life reduces replacement frequency compared to other flooring materials. A single epoxy installation might outlast 3-4 carpet replacements or 2-3 vinyl installations.

Green Certification Standards

Third-party certifications provide objective validation of environmental claims:

GREENGUARD Certification – Tests products for chemical emissions that affect indoor air quality. GREENGUARD Gold certification meets stricter standards for schools and healthcare facilities.

LEED Point Contributions – Leadership in Energy and Environmental Design (LEED) building certification awards points for sustainable flooring choices. Low-emitting epoxy systems contribute to multiple LEED categories.

Environmental Product Declarations (EPDs) – Provide lifecycle assessment data comparing environmental impacts across product categories. EPDs allow objective comparison of flooring alternatives.

Third-Party Testing – Independent laboratories verify manufacturer claims about emissions, recycled content, and performance characteristics. This testing provides confidence in environmental claims.

Certified products typically cost more than conventional alternatives but provide documented environmental benefits and often qualify for green building incentives.

Sustainable Manufacturing Practices

Leading epoxy manufacturers have adopted sustainable production methods:

Renewable Raw Materials – Plant-based ingredients replace petroleum-derived components where possible. Soy-based polyols and corn-derived additives reduce fossil fuel dependence.

Reduced Carbon Footprint – Energy-efficient manufacturing processes and renewable energy sources minimize greenhouse gas emissions. Local production reduces transportation impacts.

Responsible Waste Management – Closed-loop manufacturing systems recycle waste streams and minimize disposal requirements. Water treatment systems protect local water resources.

Local Sourcing Benefits – Regional suppliers reduce transportation distances and support local economies. Shorter supply chains also improve product freshness and quality control.

These practices add value beyond environmental benefits, often resulting in higher-quality products with better performance characteristics.

Bio-Based Epoxy Innovations

Plant-derived epoxy resins represent the cutting edge of sustainable flooring technology:

Agricultural Sources – Soybeans, corn, castor oil, and other crops provide renewable alternatives to petroleum-based resins. These materials offer comparable performance with reduced environmental impact.

Performance Characteristics – Modern bio-based systems match traditional epoxy in durability, chemical resistance, and aesthetic quality. Some bio-based products actually outperform conventional alternatives in specific applications.

Availability and Cost – Limited production keeps prices higher than conventional epoxy, but increased demand is driving costs down. More manufacturers are developing bio-based alternatives.

Future Developments – Research continues into new plant sources and improved performance characteristics. Algae-based resins and recycled plastic components show promise for next-generation products.

Top Flight Garage Floor stays current with these developments, offering the latest sustainable epoxy options to environmentally conscious customers in Rock Hill, SC.

Safety Considerations for Epoxy Flooring

Installation Safety Protocols

Professional epoxy installation requires strict safety protocols to protect both installers and building occupants:

Personal Protective Equipment (PPE) – Installers must wear appropriate respirators, safety glasses, chemical-resistant gloves, and protective clothing. Different epoxy systems require different protection levels.

Ventilation Requirements – Mechanical ventilation removes chemical vapors during installation and curing. Proper air exchange rates depend on space size, epoxy type, and temperature conditions.

Temperature and Humidity Control – Environmental conditions affect both safety and performance. Extreme temperatures can increase vapor pressure, while high humidity slows curing and creates safety risks.

Chemical Handling and Storage – Proper storage prevents accidental exposure and maintains product integrity. Temperature-controlled storage and proper labeling reduce risks.

Emergency Procedures – Trained installers know how to respond to chemical spills, exposure incidents, and other emergencies. First aid supplies and emergency contacts should always be available.

Indoor Air Quality Impact

Understanding how epoxy affects indoor air quality helps building owners make informed decisions:

VOC Emission Levels – Different epoxy systems emit different amounts of volatile organic compounds. Water-based systems typically emit fewer VOCs than solvent-based alternatives.

Off-Gassing Timelines – Most VOC emissions occur during the first 24-72 hours after installation. Complete off-gassing may take several weeks depending on environmental conditions and epoxy type.

Sensitive Occupant Considerations – Children, elderly individuals, and people with respiratory conditions may be more susceptible to chemical exposure. Special precautions may be needed for these populations.

Third-Party Air Quality Testing – Professional air quality monitoring can verify that spaces meet safety standards before reoccupancy. This testing provides objective confirmation of safe conditions.

Quality contractors provide clear timelines for safe reoccupancy and may recommend temporary relocation during installation and initial curing.

Chemical Resistance and Safety Benefits

Epoxy flooring actually improves safety in many applications through superior chemical resistance:

Protection Against Spills – Epoxy creates an impermeable barrier that prevents chemicals from penetrating concrete substrates. This protection prevents groundwater contamination and structural damage.

Easy Cleanup – Smooth epoxy surfaces allow quick cleanup of hazardous spills before they can cause harm. This capability is crucial in laboratories, workshops, and industrial facilities.

Antimicrobial Properties – Some epoxy systems include antimicrobial additives that inhibit bacterial and fungal growth. These properties benefit healthcare facilities, food processing areas, and other hygiene-critical environments.

Food Safety Applications – FDA-compliant epoxy systems meet strict requirements for food contact surfaces. These specialized coatings provide safe, cleanable surfaces in commercial kitchens and food processing facilities.

Long-term Health Considerations

Ongoing health and safety benefits of epoxy flooring include:

Maintenance Product Safety – Epoxy floors clean effectively with mild, non-toxic cleaners. This reduces exposure to harsh cleaning chemicals compared to other flooring types.

Wear Patterns and Particulate Generation – Quality epoxy resists wear and doesn’t generate dust particles like concrete or some other flooring materials. This benefit improves air quality over time.

Slip and Fall Prevention – Properly specified epoxy systems reduce slip-and-fall accidents through improved traction and visibility. Light-colored floors improve lighting conditions and hazard visibility.

Emergency Egress – Smooth epoxy surfaces facilitate emergency evacuation in commercial buildings. Clear floor markings and high visibility improve safety during emergencies.

Choosing Safe and Sustainable Epoxy Systems

Product Selection Criteria

Making informed epoxy choices requires evaluating multiple factors:

VOC Content Comparison – Compare VOC levels between different products using standardized testing methods. Lower VOC content generally indicates better environmental performance.

Environmental Certifications – Look for GREENGUARD, Cradle to Cradle, or other third-party certifications. These programs provide independent verification of environmental claims.

Performance Specifications – Match epoxy performance characteristics to intended use requirements. Over-specifying wastes resources, while under-specifying leads to premature failure.

Local Building Codes – Verify that selected systems meet local building code requirements for the intended application. Some jurisdictions have specific requirements for schools, healthcare facilities, or other building types.

Health and Safety Data Sheets – Review manufacturer safety data for complete information about potential hazards, handling requirements, and emergency procedures.

Application Best Practices for Safety

Safe epoxy installation requires attention to proper procedures:

Surface Preparation Safety – Concrete grinding and shot blasting generate silica dust that requires proper containment and respiratory protection. OSHA regulations specify strict requirements for silica exposure.

Safe Mixing Procedures – Accurate mixing ratios and proper techniques prevent exposure to uncured chemicals. Mechanical mixing equipment reduces manual handling requirements.

Curing Time Management – Proper curing time ensures complete chemical reactions and minimizes ongoing emissions. Rushing the process can compromise both safety and performance.

Post-Installation Ventilation – Continued ventilation during the curing process removes residual vapors and accelerates the completion of chemical reactions.

Contractor Qualification for Eco-Friendly Installation

Choosing qualified contractors is essential for sustainable epoxy installation:

Training in Low-VOC Systems – Specialized training helps contractors understand the unique requirements of eco-friendly epoxy systems. Different products may require modified application techniques.

Proper Equipment – Professional-grade mixing, application, and ventilation equipment improves both safety and results. Contractors should invest in appropriate tools for sustainable products.

Environmental Compliance – Knowledge of environmental regulations and green building requirements helps contractors meet project specifications and certification requirements.

Waste Disposal Practices – Responsible disposal of epoxy waste, containers, and contaminated materials protects environmental and human health. Certified contractors follow proper disposal protocols.

Maintenance for Long-term Safety and Sustainability

Eco-Friendly Cleaning Methods

Sustainable maintenance practices extend epoxy life while protecting environmental and human health:

Non-Toxic Cleaning Products – Mild detergents and specialty floor cleaners maintain epoxy appearance without introducing harmful chemicals to indoor environments.

Water Conservation Strategies – Efficient cleaning methods minimize water usage while maintaining cleanliness standards. Microfiber mops and appropriate dilution ratios reduce waste.

Sustainable Maintenance Schedules – Regular maintenance prevents major cleaning needs that might require harsh chemicals or excessive water usage.

Indoor Air Quality Protection – Avoiding harsh cleaning chemicals maintains the indoor air quality benefits that eco-friendly epoxy provides.

Extending Floor Life Sustainably

Preventive maintenance approaches maximize epoxy service life:

Preventive Maintenance Techniques – Regular inspection, prompt spill cleanup, and protective measures prevent minor issues from becoming major problems.

Spot Repair Methods – Localized repairs extend overall floor life without requiring complete replacement. This approach conserves materials and reduces waste.

Recoating Strategies – Strategic recoating can renew epoxy appearance and performance at a fraction of replacement cost. This approach maximizes the value of the original installation.

End-of-Life Planning – Planning for eventual replacement includes consideration of recycling options and sustainable disposal methods.

Cost-Benefit Analysis: Eco-Friendly vs. Traditional

Initial Investment Comparisons

Understanding the cost implications of sustainable epoxy choices:

Premium Costs – Eco-friendly epoxy systems typically cost 10-30% more than conventional alternatives. This premium reflects advanced chemistry and sustainable raw materials.

Long-Term Value – Extended service life and reduced maintenance requirements often offset higher initial costs over the floor’s lifetime.

Energy Savings – Reflective properties of light-colored epoxy reduce lighting costs throughout the floor’s service life. These savings accumulate significantly over time.

Health Cost Avoidance – Better indoor air quality may reduce health-related costs, though these benefits are difficult to quantify precisely.

Return on Investment Calculations

Financial benefits of sustainable epoxy include:

Durability Benefits – Longer service life reduces replacement frequency and associated costs. Quality epoxy installations often outlast multiple alternative flooring replacements.

Maintenance Savings – Easy cleaning and low maintenance requirements reduce ongoing costs compared to other flooring types.

Property Value Improvements – Quality epoxy flooring can increase property values, particularly in commercial and industrial applications.

Green Building Incentives – LEED certification and other green building programs may provide tax incentives or other financial benefits that offset premium costs.

Many years of experience has shown Top Flight Garage Floor that sustainable epoxy systems often provide better long-term value despite higher initial costs.

Making Informed Epoxy Decisions

The myths surrounding epoxy flooring have persisted too long, preventing people from making smart flooring choices. Modern epoxy technology offers safe, sustainable, and high-performance solutions that address environmental concerns while providing superior results.

Eco-friendly epoxy options continue expanding as manufacturers develop new formulations and sustainable practices. These advances make it possible to choose flooring that protects both human health and environmental quality without compromising performance or aesthetics.

Professional installation remains crucial for achieving the safety and performance benefits that modern epoxy systems can provide. Qualified contractors understand the unique requirements of sustainable epoxy systems and can recommend the right products for each application.

The reality is that today’s epoxy flooring options offer more choices, better performance, and greater environmental responsibility than ever before. Don’t let outdated myths prevent you from discovering these advantages for your next flooring project.